Extrusion of plastic raw material heating, which is a viscous flow state, under the pressure effect, through the extrusion die and become cross section and export mode is similar to the shape of the continuum, then cooling and shaping glass, by cutting and plastic products with a certain shape and size.

Such as in the extruder on the material is heated and pressed, to become molten flow state, and then die from the continuous extrusion and molding, extrusion. This method can produce tube, tube, rod, film, sheet, different shapes, wires, etc..

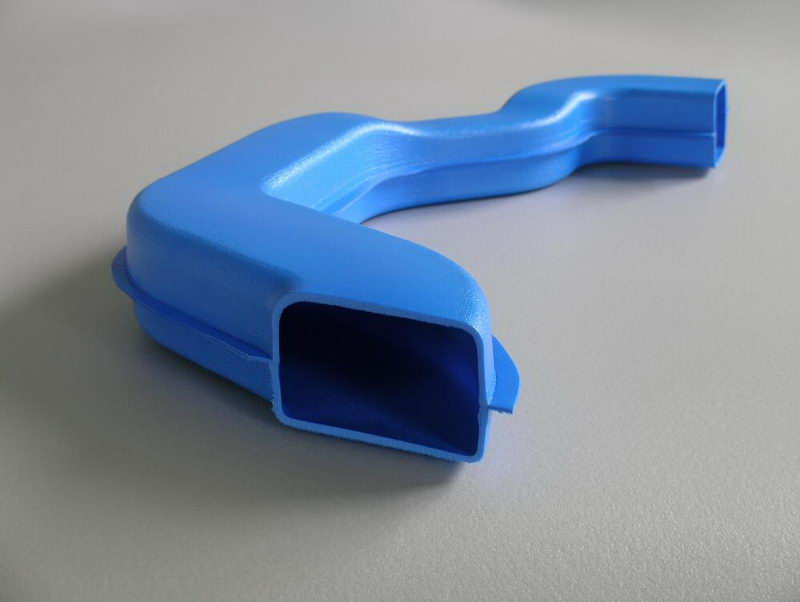

Extrusion blow molding is a kind of method for making hollow thermoplastic parts. Well known blow molded objects are bottles, cans, cans, boxes and containers of all packaged foods, beverages, cosmetics, pharmaceuticals, and daily necessities. Large blow containers are typically used for chemical products, lubricants, and bulk materials. Other blow molded products and balls, bellows and toys. For the automobile manufacturing industry, the fuel tank, the car shock absorber, the seat back, the center bracket and the arm rest and the head pillow cover are blown. For machinery and furniture manufacturing industry, the blow molding parts with shell, door frame, the system frame, pottery, or to have an open sided box.